The fit between the component design and the ability of a roll form machine or mill to form your component are linked to these characteristics. Two high rolling mills.

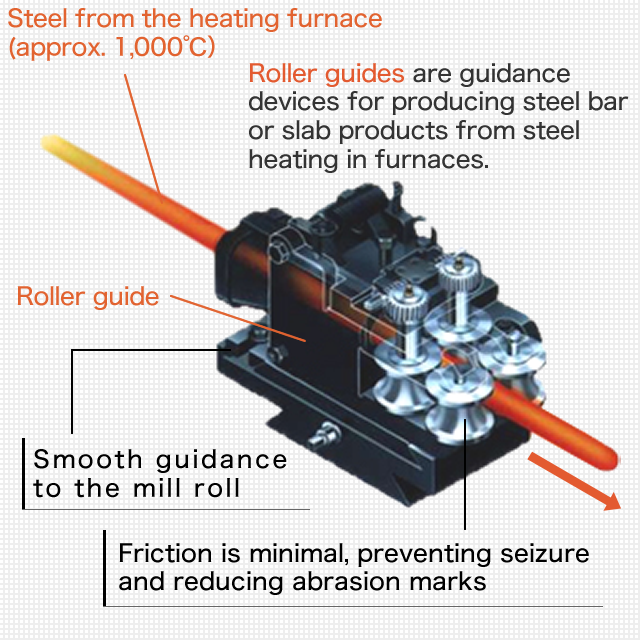

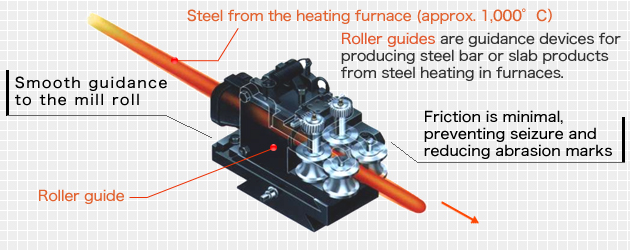

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Cantilever compact mill stands are.

. Connect with sellers directly. All the rest is shown on picture. Two High Rolling Mills.

Produce a Bend Progression or Flower. Ad Browse used roll mills on the leading machinery marketplace. At the same time the hardness of the working surface of the roll is also one of the main quality indexes of the roll.

Rolling mill is used to reduce successively the thickness of the metal strip as per the requirement. Develop a cross-sectional drawing with part material and mill specificationstolerances. We are catering to the requirement of Long Rolling Mills from 50000 TPY to 1 Million TPY on turnkey basis.

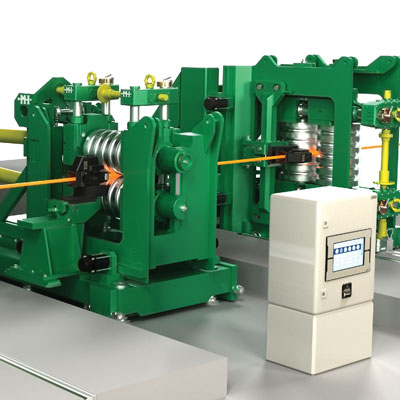

Roller guide box finds applications in continuous rolling operations in which the stock that is being rolled is properly twisted between each two adjacent rollers in rolling mills. Features of the Rolling Mill Guides Our mill guide has excellent features such as corrosive resistance unique design and simple maintenance. Most rolling mills feature two or more rolls arranged in a symmetrical pattern with half above the work and half below the work to be rolled.

We provide the best quality of mill guides at a lower price. Our roller entry guide is made in sliding type plus rolling type. The rolls of rolling mill consist of three parts.

The roller guide boxes have simple design which ensures durability standards easy installation and smooth operation in diverse rolling conditions. For each new tooling requirement the designer should use the following steps. Tendem or Continuous mills.

It contains two heavy rolls fixed one over the other. Four high rolling mills. Oct 1 2018 - Explore Navanites board Rolling Mill Patterns Designs on Pinterest.

Hotion could develop and produce all kinds of mill guides for different rolling mill. We Have a Wide Variety of Rolling Mill Models to Choose From. Mill guides also could increase the strength of surface of billet.

Provide rolling mill solutions including rolling passes design production line setup and workshop layout according to your requirements. Reconditioned roll mills listings updated daily. Durston rolling mills range from an entry-level 80mm long mill right up to 200mm.

Ad Developed to CrushGrind Various Materials with an Optimum Result. Ad Pepetools is your one stop shop for all your rolling mill needs. Lets look at some of the typical design characteristics of a roll form machine.

The rolls are supported in bearing housed in sturdy upright frames called stands which are grouted to the rolling mill floor. They are used to flatten and reduce metal to a sheet or plate. Our rolling mill guides box is offered with the.

Roll shaft spacing vertical in particular Number of forming stations. Calculate the Estimated Strip Width. Rolling mills having single-stand type are.

See more ideas about rolling mill jewelry techniques jewelry making. Rolling mills are machines that shape metal by passing it through two rolls. Then rotation goes through the gear to both of shoulders.

The present invention is characterized in that known stripper guides disposed adjacent to the work rolls of a rolling mill are provided with a pair of rolls which are disposed respectively above. In in-plant-made mills there is a control option presented by toggle. The size of the mills you choose is a personal choice based on the usage you foresee but remember the longer the mills the greater the flexibility so think about your needs now and likely needs in the future to make sure you pick something you can grow with.

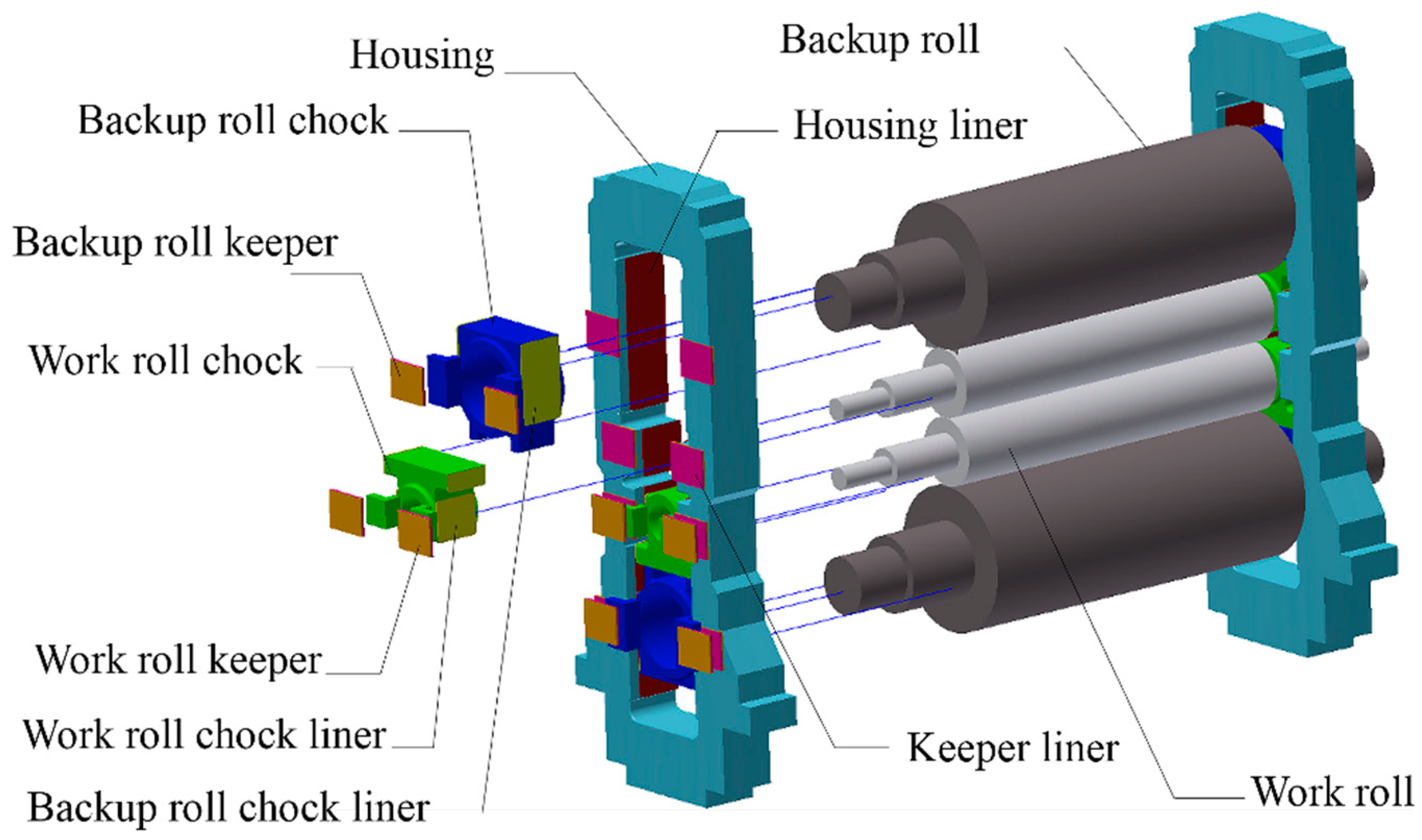

The housing less stands are normally arranged in horizontal-vertical no twist arrangement which allows no twist rolling which permits larger reduction and smoother rolling as it eliminates twisting oval into round passes as in the conventional oval to round sequence which results in less guide wear and simpler guide design. We have experience from decades in design and supply of rolling mill equipment. Layout and design the Roll Forming Tooling around the flower.

I have set of calibrated plates for this purpose it makes selection issue not complicated. Three high rolling mills. The rolls should have sufficient strength stiffness and good wear resistance.

Typically the rolls are mounted one above the other and rotate. It is a combination of software and hardware design concept. Hot rolling mills are used for mass thickness reduction at high temperatures whereas the cold rolling mills are used as secondary rolling operations to attain more precise dimensional and mechanical properties.

Here each shoulder should be aligned individually. Eight optimization steps pass schedule generation work roll determination backup. Surplus Record established 1924.

Mill guides could clear oxide scale of billet and make the surface of billet more smooth. Mill guides are to help billet safely pass through rolling mill. It is provided with heavy taper roller bearings for different sections.

Rolling Mill Guides Morgardshammar

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Rolling Mill Guide Equipments Ispatguru

Ebay Sponsored Manual Rolling Mill Machine 85mm Wire Flat Pattern Sheet Metal Jewelry Tool Us Rolling Mill Jewelry Tools Patterned Sheets

Sheet Rolling Mills Major Six Types Of Rolling Mills

Metals Free Full Text Effect Of Clearances In Mill Stands On Strip End Motion During Finishing Rolling Html

0 comments

Post a Comment